Automated Gaging Systems

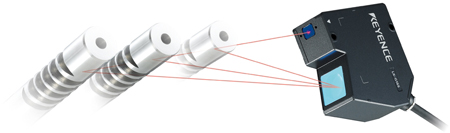

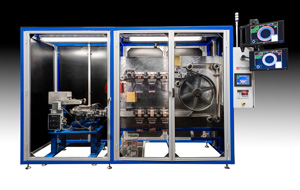

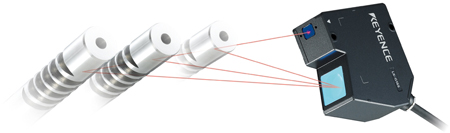

Cincinnati Automation specializes in providing state-of-the-art automated gaging systems designed to measure critical dimensions such as runout, inner diameter (ID), outer diameter (OD), thickness, length, and 2D profiles of both formed and precision machined parts. Our solutions ensure every part meets stringent quality criteria, achieving unparalleled accuracy and consistency in production processes. Utilizing both contact and non-contact sensors or probes, crucial for industries where even the smallest deviations matter. Programmable sensors allow our systems to adapt to a wide variety of parts, ensuring versatility in any production environment.

Our comprehensive 2D and 3D gaging systems can verify the full shape and size of components, providing detailed measurements and analysis for complete part validation. This advanced technology ensures all dimensions are within specified tolerances, enhancing overall product quality and reliability. With Cincinnati Automation’s gaging systems, you can confidently ensure the integrity of your parts and the efficiency of your manufacturing processes.

Our comprehensive 2D and 3D gaging systems can verify the full shape and size of components, providing detailed measurements and analysis for complete part validation. This advanced technology ensures all dimensions are within specified tolerances, enhancing overall product quality and reliability. With Cincinnati Automation’s gaging systems, you can confidently ensure the integrity of your parts and the efficiency of your manufacturing processes.

Key Benefits of Our Automated Gaging Systems:

- Versatile for a wide range of parts and applications

- Utilizes both contact and non-contact sensors

- Comprehensive 2D and 3D measurement capabilities

- Ensures all dimensions meet stringent quality standards

- Enhances overall product quality and manufacturing efficiency

-

CUSTOM SOLUTIONS

Tailored automation systems designed to meet your unique inspection and production needs, ensuring optimal performance and precision. -

SERVING ALL INDUSTRIES

Specializing in the manufacturing sector, we provide precise and consistent quality assurance that empowers companies in automotive, aerospace, consumer products, medical devices, pharmaceuticals and more, to enhance operational efficiency and uphold high standards. -

INCREASED EFFICIENCY

Increasing efficiency by streamlining the inspection process, reducing manual labor, and delivering real-time data for quicker decision-making.